Intelligent Management of Electric System in Industries - I

The automation of public electricity distribution has developed very quickly in the past few years. We can use the same basis to develop new intelligent applications for electricity distribution networks in industrial plants. Today many new applications have to be introduced as there is a need in the industrial sector and due to different environmental changes.

In this blog, we can see the system description of industrial electric system management and look on the requirements of new applications and methods that can be used to solve problems in the areas of distribution management and condition monitoring of industrial networks.

Introduction

Industrial plants have put incessant pressure on the advanced process automation. However, there has not been so much focus on the automation of the electricity division networks. Although, the uninterrupted electricity distribution is one basic requirement for the process. " disturbance in electricity supply has caused the "downrun" of the process and this may cost the huge loss of amount. Thus, the intelligent management of electricity distribution including, for example, defensive condition monitoring and on-line reliability analysis has a great importance. These days the above needs have aroused the increased interest in the electricity distribution automation of industrial plants.

The automation of public electricity distribution has developed very rapidly in the past few years. There were very promising results gained. For example, there was a decrease in outage times of customers. However, the same concept as such cannot be applied in the field of industrial electricity distribution, as the bases of automation systems are common. This is because of infrastructures of different industry plants vary more from each other, and as compared to the public electricity distribution, which is the more standardized domain. The automation devices, computer systems, and databases are not at the same level and the integration of them is more complex.

Applications for Supporting the Public Distribution Network Management

It was seen already by the end of the 80's that the conventional automation system (i.e. SCADA) cannot solve all the problems involved in network operation. On the other hand, the different computer systems ( e.g. AM/FM/GIS) include the vast amount of data which are useful in network operations. While these operators had a considerable heuristic knowledge to be utilized, too. Thus, new tools for practical problems were called for, to which AI-based methods ( e.g. object-oriented approach, rule-based technique, fuzzy sets, and uncertainty modeling, hypertext technique, genetic algorithms, and neural networks) offers new problem-solving methods. So far a computer system entity, called as a distribution management system (DMS), has been developed. This DMS is a part of an integrated environment composed of the SCADA, distribution automation (e.g. microprocessor based protection relays), the network database (i.e. AM/FM/GIS), the geographical database, the customer database, and the automatic telephone answering machine systems. While the DMS include many intelligent applications which are needed in network operations. Such applications are, for example, normal state-monitoring and optimization, real-time network calculations, short term load forecasting, switching planning, and fault management.

The core of the whole DMS is the dynamic object-oriented network model. The distribution network is modeled as dynamic objects which are again generated based on the network database or will be able to read from the network database. While this network model includes the real-time state of the network (e.g. topology and loads), and different network operation tasks call for different kinds of problem-solving methods. However, There are various modules that can operate interactively with each other through the network model, and works as a blackboard (e.g. the results of load flow calculations are stored in the network model, where they are accessible in all other modules for different purposes). although the present DMS is a Windows NT -program implemented by visual C++. The prototyping meant the iteration loop of knowledge acquisition, modeling, implementation, and testing. These prototype versions are tested in a real environment from the very beginning. Thus, the feedback on new inference models, user-interface, and external connections are obtained at a very early stage. The aim of a real application in the technical sense which was thus been achieved. The DMS entity was tested in the pilot company, Koillis-Satakunnan Sahko Oy, having about 1000 sharing substations and 1400 km of 20 kV feeders. In this pilot company, different versions of the fault location module have been used in the past years in over 300 real faults; and most of the faults have been located with an accuracy of some 100 meters, while the distance of a fault from the feeding point has been from a few to tens of kilometers. While the fault location system has been one reason for the reduced outage times of customers (i.e. about 50% in the eight past years) together with other automation.

However, the experiences as a whole were so encouraging that the DMS is modified as a commercial product. While the vendor was first a small Finnish software company. Since1997 the DMS has been a worldwide software product of ABB Transmit Oybeing integrated to the Micro SCADA platform. Today, the DMS is in everyday use in several distribution companies all over the world; and part of the research group behind the development of the DMS works at present as the employees of ABB which has confirmed the successful commercially phase.

Description of the System Environment

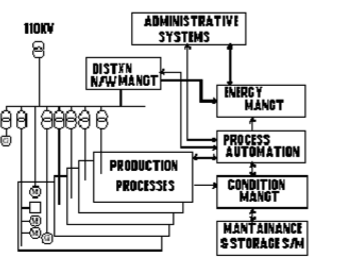

A big industrial plant differs from public distribution company by an organizatory structure and by system environment. A production is divided into many departments or many- companies. While these units have the responsibility of production and maintenance. very often the maintenance is maintained by a service company. An energy department or company is in charge of local energy production of a distribution network. Above organizations may have some control systems that serve their needs only, but usually, information systems are closely connected together. However, the process automation system is the most important system in an industrial plant, sometimes including other systems, as illustrated in the below figure. For example, all energy production and distribution network control tasks can be done in a process automation system. This is because of the reliability reasons, vital parts of distribution network control are independent of the process of automation. However, the independency of automation process system vendor has been one of the reasons for separate systems, too.

The systems in the above figure utilize many databases, which contain data that can be used in new applications. However, the process automation systems collect data for process monitoring and optimization tools. These databases contain information of material flow, energy flow, and control data of production machines. Though maintenance of such databases includes technical specifications and condition data of production machine components. Comparable information of electricity network components is supported by network database. Production programs are stored in the databases of administrative systems.

Intelligent applications are needed to:

- Handle large amount of information available; this includes filtering of data and producing new information by collecting data.

- Illustrate complex dependencies of electricity distribution and production processes in irregular situations.

- Give instructions for operators in fault situations. " risk of misoperation in abnormal fault situation is obvious and prevents or holdup operators 'decision making.

- Automize analysis tasks. Continuous information analysis is not possible manually.

In order to introduce new intelligent applications for the management of electric systems in industrial plants, a basis for implementation is needed. The following requirements should be satisfied:

- Documentation of electricity distribution network is available for the systems.

- Network databases can supply this information

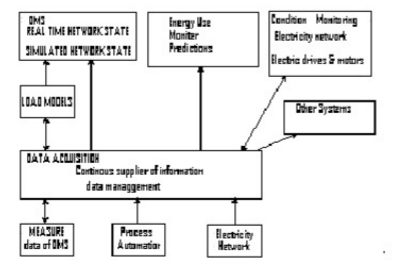

Network, process and motor measurements are available for the system. This means that Data acquisition from multiple sources with the capability to use various data transfer methods is needed, as illustrated in the below figure of Data acquisition from multiple sources.

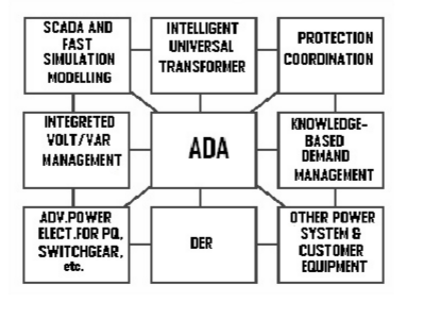

Advanced Distribution Automation

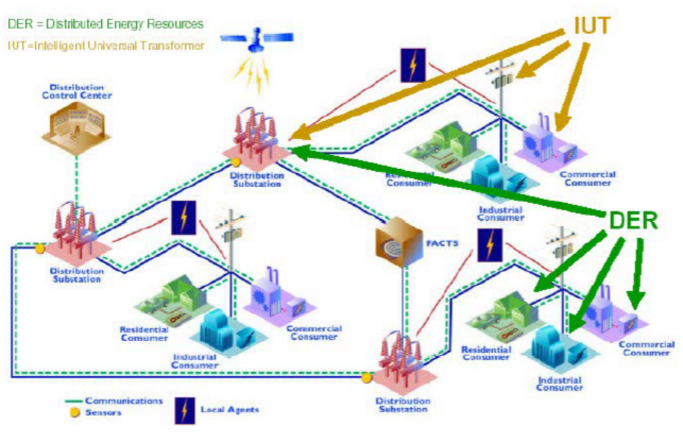

Traditional distribution systems were designed to perform one function distributing power to end users. The distribution system of the future will be more versatile and will be multifunctional.

Strategic drivers for ADA are to:

- Improve System performance

- Reduces the outage times

- Allow the efficient use of distributed energy resources

- Provide the customer more choices and

- To integrate the customer systems

For ADA to work, the various intelligent devices must be interoperable both in the electric system architecture and in the communication and control architecture.

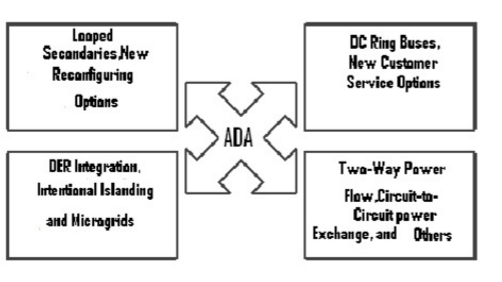

ADA will enable the distribution system to be configured in new ways and for such things as looped secondaries or intentional islanding to facilitate easy recovery from outages and to deal with other emergencies.

The three major components of ADA:

- Flexible electrical system architecture

- Real-time state estimation tools

- Communication and control system based on open architecture standards

The intelligent universal transformer is a prime example of a new electronic device that will be a cornerstone of ADA. It will provide a variety of functions including

- Voltage stepping

- Voltage regulation

- Power quality enhancement

- New customer service options such as DC power output

- Power electronic replacement for conventional copper and iron transformers

The flexible Electric Architecture and the Open communications Architecture synergistically empower each other to create the distribution system of the future.

ADA will provide improvements in many areas including:

- Reliability

- System performance

- Condition monitoring

- Outage detection and restoration

- Reactive power and voltage management

- Maintenance practices and prioritization

- Automated switching and fault management

- Customer service options

- Loss reduction and load management

Distribution System of Future with ADA

Distribution Management Functions

Distribution management functions form an entity of applications supporting documentation of network data, and planning, operation and reliability management of distribution network in industrial plants. The functions can be included in different computer systems, like AM/FM/GIS, Distribution Management System (DMS), and SCADA or case specific customized applications. The main functions of distribution management entity for the industrial networks are listed in the following:

- Documentation of network data

- Graphical user interfaces

- Real-time network monitoring, state estimation and optimization

Topology management, load flow and fault current calculation, monitoring and compensation of reactive power, monitoring of harmonics and resonance, and minimization of power losses.

Planning and simulation of operation actions

- Switching planning, fault situations, automatic load shedding and forming a local island

Management of disturbances and reliability

- Preventive condition monitoring, reliability and availability management, protection relay coordination, event analysis, fault location and network restoration, reporting.

Caused by the features of industrial networks the importance of the distribution management functions is different as in public electricity networks. There are also needs for new methods. An essential need is the load modeling which differs considerably from the public distribution. Predictive condition monitoring, reliability management, and protection relay coordination to prevent disturbances in advance have a great importance. Some functions of the DMS for the management of public distribution networks can be applied almost as such also in the management of industrial electricity networks, e.g. topology management.